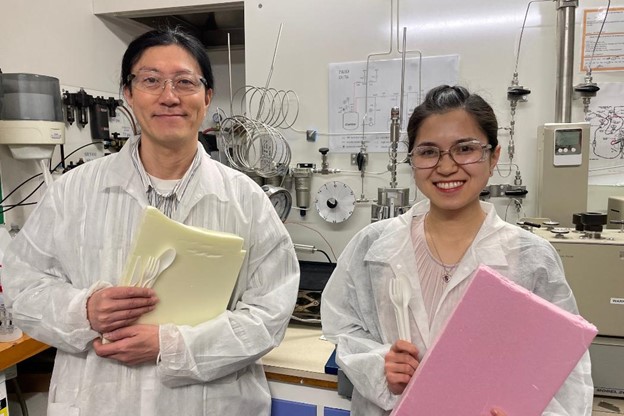

Food-safe packaging without an environmental downside: plastics manufactured with the additive feature a custom stall period that delays the onset of decomposition if not recycled.

Australia-based Twelve8 Technology has launched a plastics additive that enables polymers blended with it to decompose naturally, without industrial treatment, within two years. The PaktoEarth RAWS-Tech additive decomposes to water, carbon dioxide (CO2), and less than 1% biomass.

The additive-blended plastic, which is suitable for food packaging, can be recycled. But for post-consumer plastic that “escapes” the recycling process, ending up in nature or landfill, the technology offers an accelerated end of life vs. conventional plastics, which may take hundreds of years to degrade.

“Plastic is a massive threat to our environment. Recycling is a must but not always possible and not always achieved — 84% of plastic waste in Australia ends up in landfill,” Anthony Harrison, CEO, Twelve8 Technology, tells PlasticsToday. “We’re like eco-insurance that takes care of escaped plastic whilst alternatives are found.”

Twelve8 has distribution rights to the additive technology, which was developed by the manufacturer and intellectual property holder Green Notion with technical support by the Nano and Advanced Materials Institute (NAMI) in Hong Kong.

Australia-based Twelve8 Technology has launched a plastics additive that enables polymers blended with it to decompose naturally, without industrial treatment, within two years. The PaktoEarth RAWS-Tech additive decomposes to water, carbon dioxide (CO2), and less than 1% biomass.

The additive-blended plastic, which is suitable for food packaging, can be recycled. But for post-consumer plastic that “escapes” the recycling process, ending up in nature or landfill, the technology offers an accelerated end of life vs. conventional plastics, which may take hundreds of years to degrade.

“Plastic is a massive threat to our environment. Recycling is a must but not always possible and not always achieved — 84% of plastic waste in Australia ends up in landfill,” Anthony Harrison, CEO, Twelve8 Technology, tells PlasticsToday. “We’re like eco-insurance that takes care of escaped plastic whilst alternatives are found.”

Twelve8 has distribution rights to the additive technology, which was developed by the manufacturer and intellectual property holder Green Notion with technical support by the Nano and Advanced Materials Institute (NAMI) in Hong Kong.

Sold in pellet form, the patented additive is added to petrochemical-based plastic resin during manufacturing. Compatible resins are polypropylene (PP), polyethylene (PE), high-density polyethylene (HDPE), and low-density polyethylene (LDPE).

Twelve8 is currently working with polyethylene terephthalate (PET) and other polymers, but the ability to use the additive with these plastics remains “some time away,” Harrison says.

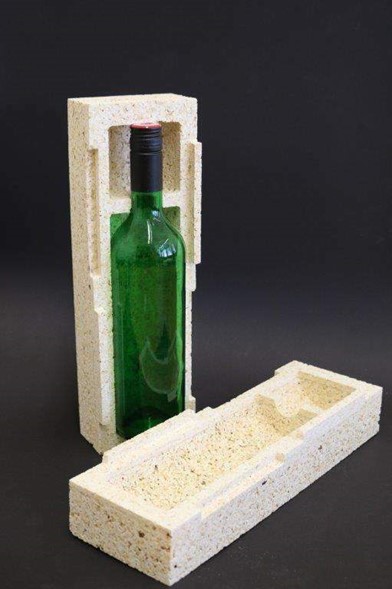

The additive-blended plastics are safe for food contact and have mechanical properties similar to the original plastics. The additive does not affect plastic manufacturing, and the resulting plastics can be blow molded, injection molded, or thermoformed. Twelve8 sells PaktoEarth RAWS-Tech in the following forms: Additive; film; plastic in which the additive has been blended with virgin and/or recycled plastic and end-user products, such as produce trays and drink cups.

Eco-friendly tech

The additive is a pro-degradant that has oxygen built in, enabling plastics to decompose anaerobically. Either sunlight or thermal atmospheric heat can activate decomposition; sunlight is not required.

During manufacturing, a delay period is built into the additive to prevent decomposition from starting too soon. This period, determined by the end user, can be from six months up to four years. “The tech has a time-controlled stall,” Harrison says. “It acts to slow down the decomposing of the plastic if it’s in the right environment.”

The stall ensures that packaging will have an appropriate shelf life for the product it holds. When the stall period has elapsed, decomposition is triggered if the temperature goes above 16⁰ C or if the material is exposed to ultraviolet light.

The first stage of decomposition is oxidization, during which a catalytic reaction breaks the plastic’s carbon-carbon bonds and introduces oxygen into the polymer chain. Ultimately, the material’s molecular weight is reduced to less than 5,000 with lab results of 2,100.

When the material reaches this molecular weight, it is no longer plastic but watery slurry called ketone that microorganisms can digest. The complete process takes less than two years. Decomposition of the additive-enhanced plastic does not result in microplastics (as does oxodegradation), and the process does not require industrial compositing conditions (as does polylactic acid, or PLA). Among other certifications, PaktoEarth RAWS-Tech has achieved ASTM 6954 Tier 1 certification for the plastic’s ability to degrade in the environment.

The additive-blended plastic is not yet certified to decompose in water should it end up in an ocean or other waterway, so for now Twelve8 is not making any related claims. However, the company’s initial testing on straws made from PaktoEarth RAWS-Tech plastic indicates that the material will break down in water. “But we will not make an official claim until we have completed all testing,” Harrison says.

In the marketplace

Applications for the additive-blended plastic include flexible packaging, such as stretch film, shrink wrap, produce bags, bread bags, and dry-cleaning bags. Rigid packaging applications include detergent bottles, milk bottles, thin-wall containers, caps, and single-use plastic items, such as cups and food containers.

Packaging based on the technology is currently in commercial use in Asia. PaktoEarth RAWS-Tech-based packaging is used at Hong Kong’s Dairy Farm retail locations, which include 7-Eleven stores. The packaging is supplied to additional customers in Hong Kong including Starbucks, Domino’s, supermarkets, and the Vitasoy brand.

Twelve8 has sales agents in North America and is in talks with potential customers in the US food processing industry, including “one of the larger poultry brands,” Harrison says. His company is also talking with a global producer of frozen chips, aka French fries.

As for the added cost of the technology, he says “It really depends on volume.” Looking at cost a different way, Harrison adds, “we’re a lot cheaper than PLA.”